The Reality Check Every Operations Manager Needs to Hear

Picture this: Your automotive parts shipment sits at the border for an extra day because you’re using the same congested routes everyone else relies on. Meanwhile, your competitor just moved 100,000 auto parts through the Arizona-Sonoran Corridor in half the time, keeping their production lines humming while yours faces delays.

This isn’t a hypothetical scenario; it’s happening right now to companies that haven’t discovered what the Arizona-Sonoran Corridor can do for their bottom line.

The $60 Billion Story That's Reshaping Cross-Border Trade

The numbers don’t lie, and they tell a compelling story. The Arizona-Sonora trade corridor generated over $60 billion in bilateral trade in 2024 alone. That’s not just statistics on a spreadsheet; that’s real money flowing through a logistics network that smart companies are already leveraging.

Here’s what caught our attention: Arizona’s exports to Mexico jumped 20.3% in December 2024, reaching $733.3 million. While imports held strong at $857.94 million, the real story is in the truck crossings—over 2 million in 2024—with Nogales handling the lion’s share as the most critical gateway for freight movement.

But here’s the part that should make every operations manager take notice: Cross-border freight between the U.S. and Mexico hit $72.5 billion in April 2024, a 15.4% increase from the previous year. Trucks carried $53.1 billion of that total, proving that ground transportation isn’t just important; it’s absolutely essential.

Accelerate Your Supply Chain Through the Arizona-Sonoran Corridor

We currently don’t sponsor visas or hire for driver positions, or any other positions inside or outside the US & Mexico.

Why Ford Chose Hermosillo (And What It Means for Your Supply Chain)

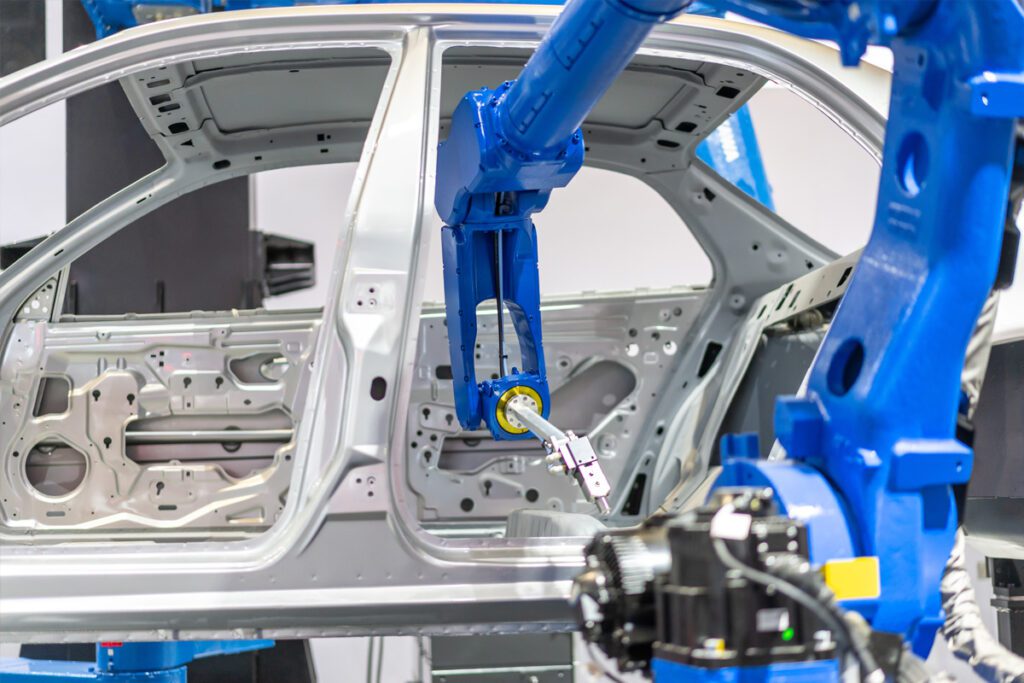

When Ford brought the new Bronco production to Hermosillo, Sonora, they weren’t just making a manufacturing decision; they were making a strategic logistics play. Ford’s presence attracted a complete ecosystem of automotive suppliers, creating a manufacturing network that includes Guaymas and Empalme, just 80 miles south.

Today we handle over 100,000 auto parts daily through this network, managing more than $11 billion worth of automotive components annually. Ford suppliers and other automotive companies have discovered what happens when lower costs, higher skills, and better employee attitudes come together in the right location with the right logistics support.

The Aerospace and Maquiladora Connection

Sonora isn’t just about automotive; it’s home to a complete ecosystem that serves automotive, aerospace, and maquiladora operations. The region’s aerospace industry benefits from proximity to key U.S. markets and a specialized workforce that understands the precision requirements these industries demand.

For maquiladora operations, the Arizona-Sonoran Corridor offers something unique: a seamless connection between manufacturing centers and distribution networks that can reduce your transportation costs by up to 40% while speeding up delivery times.

Your Logistics Solution: Why ILS Company Gets Results in the Arizona-Sonoran Corridor

Here’s what sets us apart in this booming corridor: we’re not just moving boxes; we’re managing the complete flow of goods that keeps your operations running smoothly.

Our Arizona-Sonoran Corridor Advantage

Gateway Access: We provide direct access to $32 billion worth of goods crossing through Arizona’s ports of entry. When you work with us, you’re plugging into a network that already supports 100,000 Arizona jobs tied to Mexico trade.

Strategic Location: Our logistics centers are positioned precisely where you need them close to air and ground transportation services throughout Sonora. Whether you’re moving parts to Ford’s Hermosillo plant or shipping finished goods through the Port of Guaymas, we’re already there.

Complete Service Integration: We handle international transportation (FTL, LTL, air, ocean), warehousing (inventory control, distribution, VMI, cross-docking), and complete import/export services with both Mexican and U.S. customs brokerage clearance for true door-to-door shipments.

The Guaymas Port Opportunity

Mexico’s $600 million investment in expanding the Port of Guaymas isn’t just infrastructure spending; it’s creating a major North American import center that will serve burgeoning Asian markets. We’re already positioned to help you take advantage of this expansion, whether you’re bringing components in or shipping finished products out.

Real Solutions for Real Operations Challenges

For Automotive Operations: We ensure continuous flow of components with JIT delivery systems that keep production lines moving. Our specialized equipment and inventory management systems handle everything from small electronic components to large automotive assemblies.

For aerospace companies: We understand the precision and documentation requirements aerospace operations demand. Our customs brokerage services ensure compliance, while our specialized handling protects sensitive components throughout the supply chain.

For Maquiladora Operations: We provide the cross-docking and assembly fulfillment services that make maquiladora operations profitable, plus the inventory control systems that help you manage costs and maintain quality.

Ready to Cut Your

Transportation Costs?

Smart companies are already positioning themselves to take advantage of this infrastructure investment. The question isn’t whether the Arizona-Sonoran Corridor will transform cross-border logistics, it’s whether your company will be ready to benefit from that transformation.